Case Study

The Ship – Plymouth

The Ship spirit of free enterprise – Plymouth

THE CLIENT

JCW Energy Services Ltd. Cambridgeshire who were the mechanical services contractor

Consulting Engineers

Consolux London

The Premises

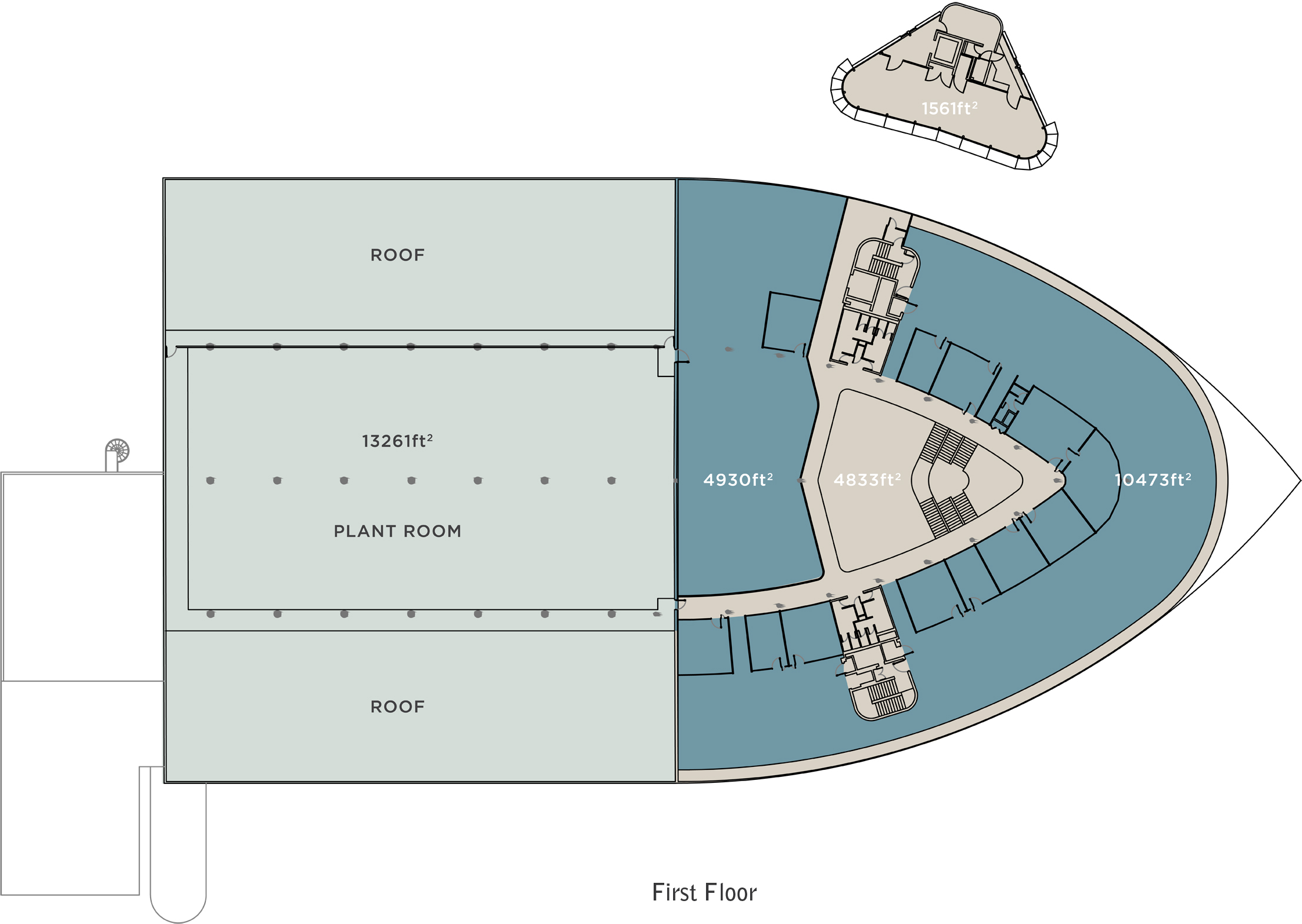

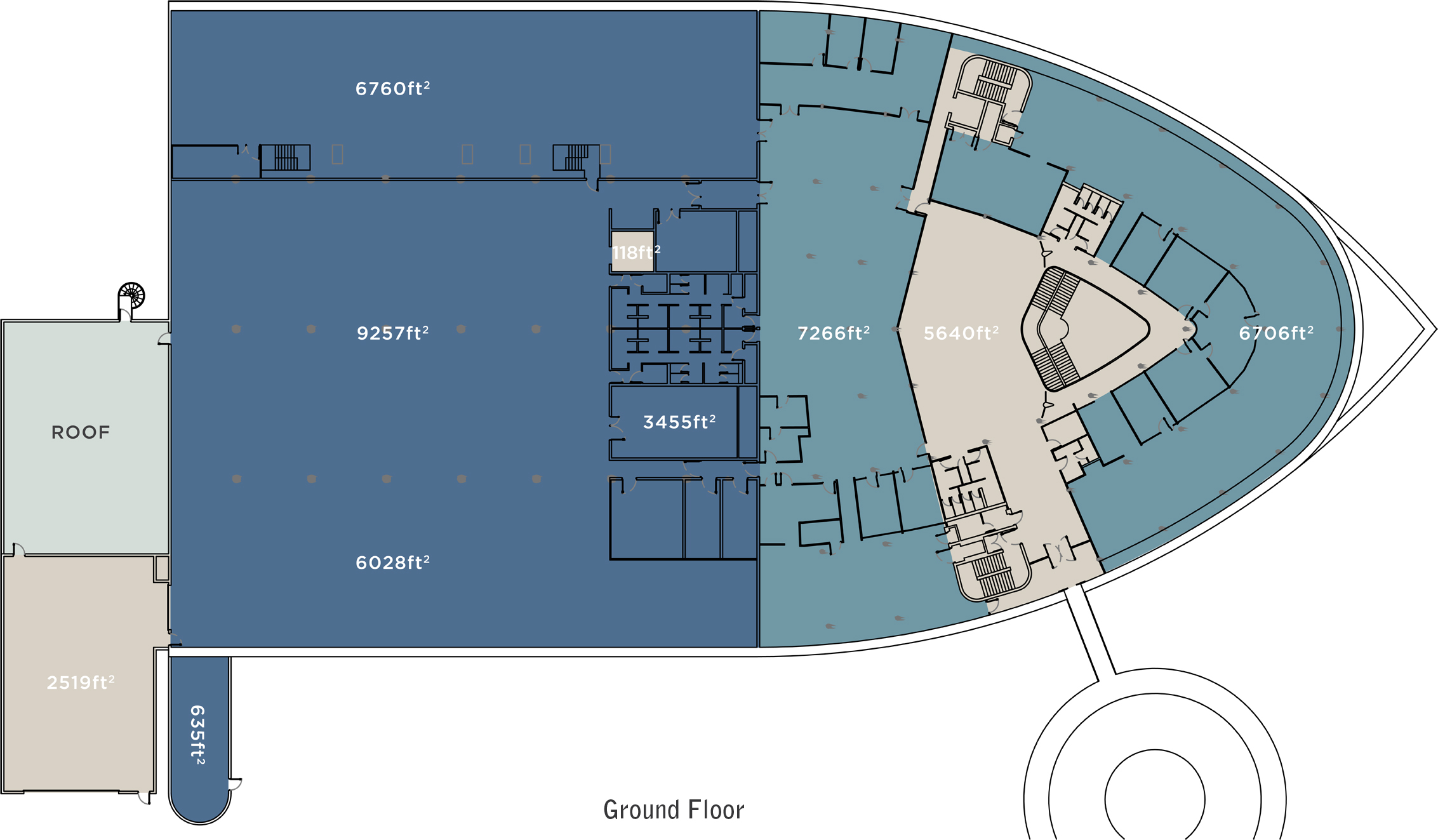

When the owners of ‘The Ship’ which is one of Plymouth’s most iconic buildings decided to upgrade the building built in 1993 they decided to name it ‘the spirit of enterprise’. The office space is on three floors with 180 degree views at the bow of the ship.

Housed at the stern of the ship, across two floors are the former industrial/commercial spaces which now has numerous alternative uses, benefitting from the huge glass walls.

The building was designed by architect Sir Nicholas Grimshaw (architect for the Eden Project and Waterloo Station). The building design collected many awards from The British Construction Industry, the Royal Fine Arts Commission Building of the year and the structural steel design contest 1993, also winning the 1994 RIBA prize.

THE PROJECT

The building was subject to a full refurbishment with 50,000sqft of office area, ground floor kitchen and restaurant, boardroom, car parking for 450 cars.

To meet low energy and carbon footprint requirements the building services designers and contractors selected heat pump air handling units from The Air Handlers Northern ‘Envirofresh 70’ range. Two award winning Envirofresh 70 heat pump air handling units were selected to provide tempered fresh air to the building.

Delivering a total of 7.5m³/sec of balance airflow fresh air/exhaust air at the following conditions.

Summer ambient |

30.0°C/21.97°C |

Winter ambient |

-5°C |

Summer supply air temperature |

18°C |

Winter supply air temperature |

24°C |

Summer return air temperature |

24°C |

Winter return air temperature |

22°C |

Each visit contained a 70% efficiency rotary thermal wheel and the units offer a high C.O.P.

Envirofresh 73 advert

Envirofresh doors on/off

INLET & OUTLET SHUT OFF OPPOSED BLADE DAMPERS HAVING AEROFOIL BLADES AND EDGE SEALS (LOW LEAKAGE).

INLET & OUTLET SHUT OFF OPPOSED BLADE DAMPERS HAVING AEROFOIL BLADES AND EDGE SEALS (LOW LEAKAGE).

ELECTRIC PRE HEAT / FROST HEATER THYRISTOR CONTROLLED WITH THERMAL CUT OUT, FAN RUN ON TIMER AND AIRFLOW PROVING.

FAN SECTION CONTAINING A E.C. FOOT MOUNTED OR PLATE MOUNTED BACKWARD CURVED CENTRIFUGAL FAN.

ROTARY THERMAL WHEEL HEAT RECOVERY SECTION COMPLIANT WITH Erp 2018 ECO DIRECTIVE.

ROTARY THERMAL WHEEL HEAT RECOVERY SECTION COMPLIANT WITH Erp 2018 ECO DIRECTIVE.

PRE FILTER SECTION WITH G4 GRADE DISPOSABLE PANEL FILTERS.

HEAT PUMP COIL SECTION.

CONTROL PANEL WITH TREND OR CAREL CONTROL SYSTEM.

Any occupied space requires the correct quantity of outside air to displace any stale air and create a fresh environment. By utilizing heat pump technology and heat recovery, envirofresh systems provide a cost effective way of installing a 100% outside air system with balanced extract. With heat recovery it is possible to increase the temperature of the fresh air towards the indoor air conditions, reducing the heating costs by 50%.

Due to building restrictions the units had to be delivered in sections resulting in refrigeration works, part assembly of the units, and controls wiring work being finished on site by our site services division.

We supply and manufacture aircraft air handling, ECE ltd, barkell envirotec, VES, nuaire, flaktwoods, air source ventilation swegon, air handling systems, air handling unit manufacturers, AHU manufacturers, school air handling unit manufacturers, heat recovery air handling units, heat pump air handling units, low profile air handling units, low noise air handling units health care air handling units, packaged air handling units, modular air units, central station air handling units.

Enquire about the products used in this project, email us sales@airhandlers.net or call us on 0161 745 8888